Главная страница Случайная страница

КАТЕГОРИИ:

АвтомобилиАстрономияБиологияГеографияДом и садДругие языкиДругоеИнформатикаИсторияКультураЛитератураЛогикаМатематикаМедицинаМеталлургияМеханикаОбразованиеОхрана трудаПедагогикаПолитикаПравоПсихологияРелигияРиторикаСоциологияСпортСтроительствоТехнологияТуризмФизикаФилософияФинансыХимияЧерчениеЭкологияЭкономикаЭлектроника

Interacting with autistic children

|

|

" There's something about the machine that puts the child at ease and makes them capable of doing what they don't otherwise do. I'm not saying they appear entirely normally developed, but for example there are children that have never shown a social smile, and they'll show that to the robot, " Mataric explains.

" What we're trying to do is use the robot as a coach, and use it as a mediator: you have the robot, a child and then another child with whom they would not behave in a social way without the robot. We're using the robot to basically train up social behaviours, so that eventually you can remove the robot, and the child can be closer to being reintegrated in a social setting."

Even Mataric herself says she's surprised that she became an engineer, she believes many people just aren't aware how vast the engineering world is.

" There's so much going on in engineering that I think people really don't realise what you could be doing as an engineer. I'd never thought I'd be an engineer, " she says.

" The whole notion of working directly with people and understanding society's needs is an incredibly powerful thing. I think people don't really realise it, because there's this stigma that an engineer is someone who is a nerd who sits in a cubicle. It's about working with people and solving interesting problems. I wish more people would understand that that's what it is, because it's really one of the most fun things you could possibly do."

Flying pet drone

Robot-maker Sameer Parekh, 38, is talking about the time he was interviewed for a post with the CIA. Back in 2000 he sold his internet startup C2Net and took time off to tour central and eastern Europe as a DJ, before returning to the US in 2001, in the aftermath of 9/11. In 2007, he applied to join both the FBI and the CIA but was rejected by the latter after failing a polygraph test (he still doesn't know what it detected). Four years later, Parekh was working at Goldman Sachs when he stumbled across the 3D-printer company MakerBot.

A powerful feeling took hold that he was wasting his life. " I realised I'd been living under a rock, that there was awesome stuff going on out there, while I was working for a bank, " says Parekh. He quit his job, eventually launching Falkor Systems, a robotics startup.

It specialises in flying bots because they combine his passions -- robotics and aviation. " There's a lot of hardware involved, but it's not like a walking robot or one that has to grab things, " he says. " A quadcopter is basically four to eight props and a gimbal."

Identifying his initial market as extreme-sports photographers, he explains: " Quadcopters are already being used [to film] rallying, skiing and base jumping, but they are all being used in a piloted way, where you've got a guy jumping off a cliff and another guy flying the robot. The goal for this product is to be autonomous and track the athlete [on its own]." Parekh, who works with two interns and " a team of hardware-adviser friends", envisages a $1, 000 (£ 660) device, featuring " a little camera with fewer control systems -- like a GoPro [camera], except it flies." It will have diverse applications, including security and oil-pipeline management. But it's his long-term vision that has caught the imagination of Grishin Robotics. " I want to build flying robotic pets, " Parekh says. " The robot would follow you everywhere, take pictures of you and your friends, tweet for you, carry your keys and do other stuff for you."

Turtlebot

In a cluttered Brooklyn workshop, Bill Morris is hunched over a mobile robotic platform. With a swipe of a tablet screen, the platform -- a TurtleBot with a Baccus open-source robotic arm attached -- lurches across the room. Morris flashes a grin. " Do you want to drive it? "

The TurtleBot is from Willow Garage, a California-based R& D lab that focuses on building hardware and open-source software for personal robotics. Morris, a former web entrepreneur in his 30s, launched I Heart Engineering in October 2010, after Willow Garage sent out an email requesting manufacturing partners. " Willow Garage open-sourced the entire [TurtleBot] project, " he says. " We often joke that we're the world's biggest developer of TurtleBot accessories."

Morris estimates that he and his team of three full-time and six part-time engineers and coders have built hundreds of TurtleBots, which he describes as an academic platform for robot-building projects. He gestures to a prototype for TurtleBot 2. " It has a fixed pattern of holes on the top of the platform, so you can mount things, " he says. " It provides wheels, Kinect or a 3D sensor to do navigation, a gyro and accelerometer to help determine position and orientation, and comes with software and a laptop. It gives you a base to start your project.

" I want to live in a robot future, where a $2m (£ 1.3m) robot I bought off eBay for $20, 000 (£ 13, 000) can fold my laundry, " he says. " In the case of technological singularity, we either have the dystopian robot future that Hollywood dreams about, or the awesome future. Robots folding laundry is how we get to awesome."

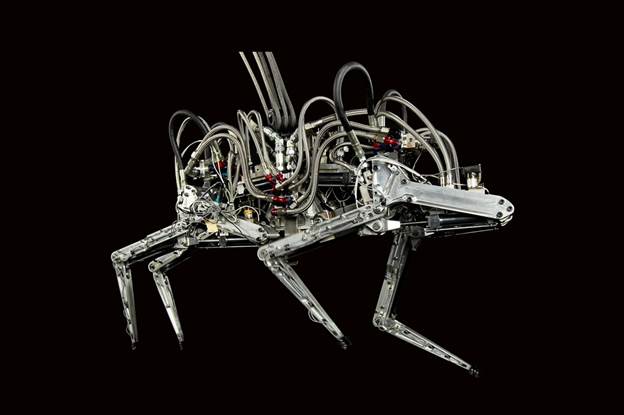

The Cheetah

The US Defense Advanced Research Project Agency is, with technology company Boston Dynamics, developing the Cheetah -- a set of mechanical legs that flex and unfurl like natural limbs and have attained speeds of 45kph.

Fish

Huosheng Hu at Essex University's School of Computer Science and Electronic Engineering heads a team that makes 1.5-metre-long robotic fish, which swim at 25cm per second. The fish can identify different types of pollution -- and their source -- by using tiny chemical sensors.

REEM-B

This 1.47-metre tall humanoid robot is REEM-B: the second avatar of REEM robots, built by PAL Robotics, a Barcelona-based team of engineers. REEM-B, unveiled in 2008 on Al Reem Island in Abu Dhabi, is capable of face-recognition and memory, dextrous movements, bipedal walking for 1.5km and stair climbing. Embedded sensors allow it to navigate the world independently: a laser range-finder, accelerometer, gyroscope and six axis-force sensors help generate maps of obstacles and building layouts. Weighing 60kg, it can carry loads of up to 25 per cent of its own weight.

RoboFold

Robot arms have traditionally welded, struck and shifted sheet metal to mass-produce cars. Gregory Epps, the founder and CEO of London startup RoboFold, has been developing their suitability for more delicate tasks. Thanks to a programme run jointly by the Royal College of Art and Imperial College in London, he and RoboFold have produced machines that can fold metal with the fine touch of an origami expert. His machines made ornate steel designs for last year's Venice Biennale and he's adapting the designs into prototype furniture and building materials. Epps hopes to develop applications suitable for both carmakers and artists - including sketching bots that can draw directly on to steel.

Kiva Systems

In May 2012 Amazon paid $775 million (£ 510 milliom) for Kiva Systems Inc, an automated order-fulfilment company whose robots stack shelves and move crates for companies including Gap. Kiva's squat bots zoom around Manhattan-style grid systems in sprawling buildings, hunting tagged products then carrying tall shelving " pods" to a queuing system where human employees pick out individual items. In Germany, the Fraunhofer Institute is developing swarm intelligence for a similar programme called MultiShuttle. Net-A-Porter recently introduced robots developed by logistics specialists TGW in its UK warehouses. Its CEO Mark Sebba says the system is 500 percent faster than humans.

Da Vinci

In 2012 the Da Vinci, a surgical robot guided by humans, conducted the UK's first robotic open-heart surgery. The machines -- developed by California's Intuitive Surgical Inc -- cut between a patient's ribs rather than cutting open the breast plate, so reducing recovery time. The prohibitive cost of the bot -- £ 1.3m, plus regular maintenance - could restrict its use until prices fall.

BionicHandlingAssistant

Festo, a supplier and developer of automation technology, modelled this robotic arm on an elephant's trunk. It provides flexible assistance over 11 degrees of freedom. It is sensitive enough to respond to accidental collisions with nearby humans, without interrupting its current task.

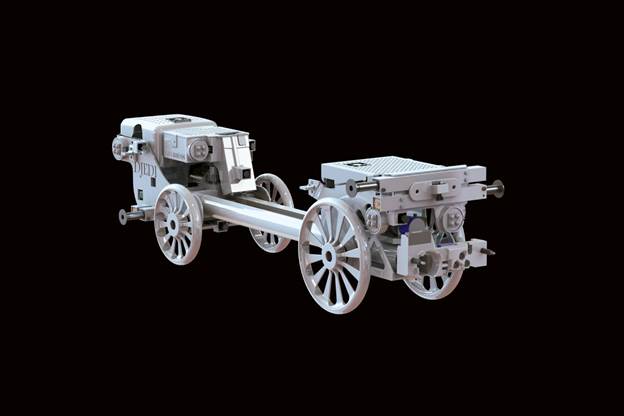

Djedi

In Egypt, robots designed to search for earthquake victims are being adapted for archaeological work. A team working on sealed chambers in the Great Pyramid of Giza asked Robert Richardson, of Leeds University's School of Mechanical Engineering, to adapt a rugged crawler bot to delve into the heart of the ancient structure.

Shadow Robot, a London-based robotics company, has developed a robot hand that has 24 joints driven by 20 motors. With such a wide range of movement, it can pick up even tricky objects, such as pencils.

During summer of this year, the company connected one of the hands to an extremely precise 3D sensor. Developed by a European Commission-funded project, the sensor lets the hand effectively " see" what to grasp by scanning the environment in front of it. Future applications could include the hand picking up a swab located by the sensor and using it to test a potentially contaminated package. " We've spent a lot of time looking at how we can put robots in places where humans currently go, which we as a society would much rather people didn't have to, " explains Rich Walker, Shadow Robot's MD. " So the classic 'difficult, dirty and dangerous'."

Walker says the original plan for the TACO (Three-Dimensional Adaptive Camera with Object Detection and Foveation) was to make a simple 3D-sensor -- " and then the Kinect came out". So the research group, which consists of seven European partners, turned up the power. The laser's 2kW peak output allows the sensor to recognise objects smaller than the Kinect can resolve.

An infrared beam shines on five oscillating micro-mirrors. It bounces off the objects in front of it and is detected by a second sensor that measures the time it took to return, and calculates the depth of the surfaces. Using object-recognition systems, a computer can match a detected object to an item in its database, then instruct the robot arm to handle it appropriately. But with such power, it's not to be toyed with. " If the beam stops scanning, whatever it's pointing at will start to burn, " says Walker. " Things catch fire with this laser."