Главная страница Случайная страница

КАТЕГОРИИ:

АвтомобилиАстрономияБиологияГеографияДом и садДругие языкиДругоеИнформатикаИсторияКультураЛитератураЛогикаМатематикаМедицинаМеталлургияМеханикаОбразованиеОхрана трудаПедагогикаПолитикаПравоПсихологияРелигияРиторикаСоциологияСпортСтроительствоТехнологияТуризмФизикаФилософияФинансыХимияЧерчениеЭкологияЭкономикаЭлектроника

Organization of dental clinic

|

|

The rooms in general dental practice are usually allocated to serve different purposes: reception, waiting room, general practice room, surgery, toilet etc.

Reception is one the most important aspects of a successful dental practice is the atmosphere surrounding the reception of patients and other callers on the telephone and at the door.

Maintenance of equipment.

To maintain the equipment, instruments and furnishings in good working order and in a high state of cleanliness and preparation.

A Dental Unit.

This contains and supports such things as the operating light, air- spray, water- spray, suction and saliva ejector, the dental engine, air –rotor and air- motor, a spittoon and a sterilizable working surface or bracket table. The unit may be a single pedestal or split into two sections on each side of the chair.

A Dental Chair.

This has either a completely adjustable backrest, headrest and back /seas angle, so that the patient lies flat.When using this flat or supine position high-speed suction becomes essential to protect the patient’s airway. The dental chair has a mechanism for raising, lowering and tilting it until the patient’s mouth is at a convenient working height for the dental surgeon.

Cabinets and trolleys.

There are best grouped as close as possible to the working area so that instruments, materials and working surfaces are conveniently to hand during treatment procedures.

Operating Stools.

When the dental team can sit down to work they will be less tired at the end of the day.

Working surfaces and the patient’s mouth height should ideally be at elbow height so that the hands and forearms are working in the least tiring position.

Sterilizing Apparatus.

Some instruments are sterilized afresh each day and then stored in covered trays.

This is a box for storing clean instruments which are ready for immediate use.

X-Ray Apparatus.

2. The general dental instrument

Hand Dental Instruments

Handpieces

There are of various types and are used to hold the engine-driven instrument firmly and transmit the motive of the engine to it. They may be:

- Straight handpieces

-Right-angled handpieces;

-Speed down handpieces

Air turbine handpieces (always used with a water spray to prevent overheating of the tooth).

MIRROR

Along with the explorer, a mouth mirror is the most widely used instrument by dentists and hygienists.

A mouth mirror enables the dentist to see all sides of the teeth and all areas of the mouth.

Mouth mirrors may have plane or magnifying surfaces and may be attached to an electric mouth lamp to improve intra-oral illumination.

EXPLORER

This instrument (along with a mouth mirror) is the instrument that a dentist uses on probably every patient. An explorer is NOT used to poke gums. The dentist uses an explorer to feel teeth, to see if there are any sticky spots that could be decay, check to see if fillings are leaking, count teeth and check the margins of crowns.

COTTON PLIER.

They look like tweezers and function the same way. Cotton pliers are also very useful to pick up small items and remove small items from the mouth. They are also used to avoid contamination.

PERIODONTAL PROBE

A periodontal probe is used by a dentist or hygienist to measure the depths of a space between the tooth and gum.

The dentist or hygienist will use a periodontal probe to measure a space between the gum and tooth. If the space is very deep, gum disease would be a concern and a deep cleaning called Root Planning or a consultation with a Periodontist (gum disease specialist) would be the next step.

The close up shot of a periodontal probe shows the lines used for measuring the space between the gums and teeth.

SPATULA

The Spatula is used by the dentist or assistant uses to mix up specific materials. The spatula is used to mix up dental materials and is not used in your mouth.

Excavators

Softened, carious dentine can be removed from cavities by using hand excavators

These have small, spoon-shaped, circular or oval tips which are very sharp around their circumference. They are pressed into the carious material and used to lever and dig large fragments. When the bulk of the caries has been removed they can be used to scrape and explore the firmer surface of the prepared tooth to eliminate any final fragments. They allow good visibility during deep excavation of a tooth and are used when there is some danger of exposing the pulp. Many different sizes of excavator tips are available and there are several basic angles of terminal shaft to allow them to be used more easily in different positions in the mouth.

Chisels:

There are used to split off unsupported enamel along the cleavage planes parallel to the enamel’s prisms and also to plane down and smooth the cavity margins. There are a straight chisel, angled or bin angled.

Matrices

When the cavity outline extends over more than a single surface of the tooth the final restoration generally has to be packed into a box shape with one wall missing. In order to contain the filling materials and allow it to be condensed properly a tooth wall has to be constructed temporarily as matrix or shaper.

Types of Matrix:

- Metal and plastic

The Rubbern Dam.

A thin sheet of rubber is perforated with a rubber dam punch and applied to the appropriate teeth so that they protrude through the prepared holes.The sheet is retained on the teeth by special spring clamps or ligatured in place around the necks of the teeth. The edges of the dam are controlled by fastening them to a frame holder. The isolated teeth are thus kept free of moisture and contamination commonly used during root canal therapy or restoration.

MOTOR DRIVEN ROTARY INSTRUMENTS USED FOR CAVITY PREPARATION

1.

2. Burs

- Fissure (cross-cut fissure, tapered fissure)

- Round (rose –head)

- Invert cone

- Wheel

- End-cutting

- Finishing (which are smoother: round, pear, oval, flame shaped)

3. Diamond instruments

- Bur shapes, fissure, round, invert cone etc.

3. Abrasive finishing pointsin many patterns

4.Brusshes and rubber polishing tips (cup and wheel shapes)

Burs

(1) Characteristics.

In discussing the preparation of a cavity for restoration in a modern clinic, it is essential that we talk about the many different kinds of burs available to the dentist. Regardless of the procedure being done, the burs will probably be used in preparing the cavity for restoration. They are manufactured in different sizes and shapes suited to the various types and forms of the cavity preparation desired. You will be expected to know four different things about the burs that you are given: The shape (name) of the working end, the series number of the bur, the material of which it is made, and in which hand piece each type of bur may be used. Series numbers and bur shapes are associated with each other: A round bur is in the ten series, an inverted cone bur is in the thirty series, a straight crosscut fissure bur is in the five hundred series, and the tapered fissure bur is in the seven hundred series. Burs may be made of one of two materials: A stainless steel bur will have a smooth shank, and a tungsten carbide alloy, bur will have a ring, a set of parallel rings, or possibly a ring of X's around the shank. Tungsten carbide burs will stay sharp longer than stainless steel burs, and they may be used repeatedly without marked reduction in cutting efficiency. There are three different hand piece attachments for the burs. The slow-speed straight hand piece (SHP) uses a friction grip attachment and accepts a bur with a long shank. This means that the end of the bur that goes into the hand piece is smooth and is held in the hand piece by friction. The shank of the straight hand piece bur is not only longer but also larger than the other burs. The bur that goes into the slow-speed contra-angle hand piece (AHP) is almost as large around as the straight handpiece bur, but it is much shorter and has a notched end with a groove opposite the working end that fits into the latch attachment on the angle hand piece. The bur for all high-speed hand pieces (HSHP) is smaller and shorter than the other burs; it also has a friction grip attachment (that is, the end is smooth). The Midwest Quiet-Air hand piece accepts the friction grip bur, but the hand piece is designed with a chuck that must be tightened on the bur. Burs are an essential part of the setup for the dentist performing a restorative procedure. They are the rotary cutting instruments that replace many of the hand instruments used in a cavity preparation procedure. You will be required to know four identifying characteristics about dental burs.

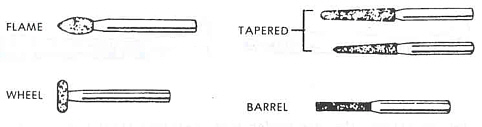

(a) The first type is a description of the shape of the working end as illustrated in figure 2-2.

Figure 2-2. Bur shapes.

NOTE: The first letter of each bur type is underlined. These four letters, in order, spell RIST. This key word will help you learn the burs in increasing numerical sequence.

(b) The second identifier is the number:

10 series--(Round bur)

30 series--(Inverted cone bur)

500 series--(Straight crosscut fissure bur)

700 series--(Tapered fissure bur)

(c) The third is composition.

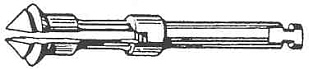

(d) The fourth is the hand piece attachment. Burs are attached to one of three hand pieces. To establish which hand piece a bur is used in, you may look at the end away from the working end, as illustrated in figure 2-3.

(e) Any of the independent factors describing burs may be combined when designing a bur. Obviously, the use and series numbers correspond with the name or shape of the bur. However, any shape bur may be made of either of the two materials, and it may be made to fit into any of the three types of hand pieces.

(2) Availability. Available stainless steel burs include the following for both AHP and SHP except as noted: round burs numbers 1/2, 2, 4, 6, and 8; inverted cone burs numbers 33 1/2, 35, 37, and 39 (39 is available for AHP only); straight crosscut fissure burs numbers 557, 558, 559, and 560 (560 is available for AHP only); and tapered crosscut fissure burs numbers 700, 701, 702. Angle hand piece steel burs numbers 4, 35, and 558 are available in either the standard or short-neck lengths. Tungsten carbide burs are available for the AHP in the same sizes except for numbers 1/2 and 560. An end-cutting tungsten carbide bur is available as number 901. The tungsten carbide burs function best at high-speed operations; they are harder than stainless steel burs. See figure 2-4. Available friction grip tungsten carbide burs include the following for high-speed angle hand pieces: round burs. Numbers 1/2, 2, 4, and 6; inverted cone burs numbers 33 1/2, 34, and 35; straight, crosscut fissure burs number 557 and 558; straight, plain fissure bur number 57; tapered, crosscut fissure burs number 699, 700, and 701; and tapered, plain fissure bur number 170L.

Figure 2-4. Friction-grip tungsten carbide bur.

b. Diamond Stones and Wheels Diamond stones and wheels (figure 2-5) are used to cut enamel and are manufactured in various sizes and shapes. These instruments create heat during use and require water or air-cooling if used for any length of time.

Motor-Driven Rotary Finishing Instruments.

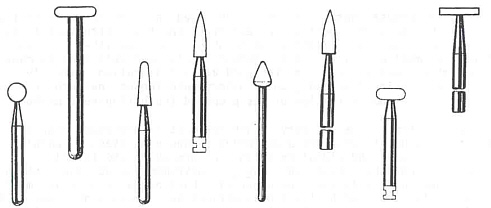

Finishing burs (figure 2-24). Finishing burs are used to even the margins and polish the surface of dental restorations. They are available in round, oval, bud, sugarloaf, and tapered fissure shapes. Round and bud shapes are available for both AHP and SHP; the remaining shapes for AHP only.

Figure 2-24. Finishing burs.

(2) Mandrels (figure 2-25). Mandrels are used to hold disks and wheels during their use. Snap-head mandrels are used only for sandpaper and linen-backed disks with a special brass center which snaps on to the mandrel. Screw-type mandrels are used to mount abrasive disks and unmounted stones.

Figure 2-25. Snap-head mandrel.

(3) Abrasive and polishing disks (figure 2-26). Disks of various diameters and surfaced with various abrasives upon different types of backings are used for purposes ranging from rapid cutting of enamel to fine polishing of restorations. They include sandpaper disks (abrasive on one side), double-cutting disks (abrasive on both sides), and diamond disks. Diamond disks must be cooled with water or air when used.

Figure 2-26. Unmounted abrasive disks, screw-in type and snap-on type.

(4) Mounted stones and wheels (figure 2-27). Mounted stones and wheels of diamond or silicon carbide are used for grinding, cutting, and polishing. They are available in ball, cone, inverted cone, cylinder, tapered cylinder, knife-edge, round-edged, and other shapes and sizes.

Figure 2-27. Mounted abrasive stones and wheels.

(5) Unmounted abrasive wheels. Abrasive wheels of various dimensions and materials are used for grinding, cutting, and polishing.

(6) Rubber polishing wheels. Rubber wheels of various sizes, unimpregnated or impregnated with pumice, are used to polish teeth and restorations.

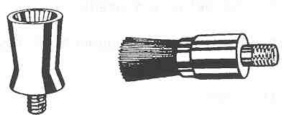

(7) Polishing cups and brushes (figure 2-28). These cups and brushes are used to polish teeth and restorations.

Figure 2-28. Polishing cup and polishing brush.