Главная страница Случайная страница

КАТЕГОРИИ:

АвтомобилиАстрономияБиологияГеографияДом и садДругие языкиДругоеИнформатикаИсторияКультураЛитератураЛогикаМатематикаМедицинаМеталлургияМеханикаОбразованиеОхрана трудаПедагогикаПолитикаПравоПсихологияРелигияРиторикаСоциологияСпортСтроительствоТехнологияТуризмФизикаФилософияФинансыХимияЧерчениеЭкологияЭкономикаЭлектроника

The Permanent Way

|

|

The permanent way is the structure consisting of the rails, sleepers (UK), or ties (US), ballast, fasteners, or fastenings, including rail anchors, as well as turnouts, bridge timbers, and crossing sleepers. The permanent way has to be made strong, stable and to provide safety and smooth running of passing trains.

Complete sections of track – rails and sleepers – may be prefabricated and laid in the track by mechanical means.

Rails. Rails guide wheels of rolling stock. Railway rails are subject to very high stresses and have to be made strong, durable, and reliable. Heavier rail can support heavier and faster trains than lighter rail. Rails are made of very high quality steel alloy including iron (Fe), carbon (C), manganese (Mn), silicon (Si), and phosphorus (P).

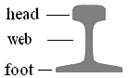

Cross-section of rail

Cross-section of rail

Rail consists of a head, a web, and a foot (or base). In Russia, rail is graded in kilograms per metre (kg/m). Standard rail types are R50, R65, and R75. The choice of a rail type depends on traffic density, axle loads, and train speeds. Rails are produced of a standard length of 25 metres. Besides, shorter rails are used on curves and turnouts. Like other elements of the permanent way, worn heavy rails from a mainline are often reused on branch lines, sidings and yards. One of the most important developments is the welding of standard rails into long lengths. This continuous welded rail results in a smoother track that requires less maintenance.

Fastenings. Anchors. The rail and the chair are fixed to the sleeper with the spike, a large nail with an offset head. Besides, the chair itself can be fixed to the sleeper with an additional spike.

Fastenings for wooden sleepers. 1 – rail; 2 – spike; 3 – chair; 4 – sleeper

The method of separate fastening is not as cheap and simple as the previous one, but it has a number of advantages. It gives greater resistance to loosening and keeps the rail in gauge. In addition, it does not require measures to prevent rail creeping. The rail is fixed to the chairs with the clips and the clip bolts, and the chairs to the sleepers – with the bolts and the screws.

Fastenings for concrete sleepers

The rails are bolted to each other (Fig. 5) by means of fishplates to make a continuous rail line. The bolts (usually four, but sometimes six bolts per joint) may be oppositely-oriented. They pass through holes in a rail web and a fishplate.

Rail fastenings

The place where ends of rails meet is called a joint. In hot weather rails expand, so a small gap is left between rails which does not exceed 21mm.

Insulated joints are required on track circuit sections so that the electric current cannot flow from one rail to another. There are two types of insulated joints: 1) joints with joint liners and 2) glued joints, where all the gaps are filled with epoxy resin.

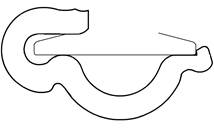

To prevent the rail creeping, anchors are used. There are spring anchors and wedge anchors. A spring anchor is lighter than a wedge one, consists of only one part, is successfully used both on single and double track lines, and requires less maintenance.

A spring anchor

| Did you know? A sleeper in the UK is called a tie (or a crosstie) in the USA. |

Sleepers. Sleepers, supports for the rails, transfer loads to the ballast and subgrade, hold the rails upright, and keep them spaced to the correct gauge. Traditionally, sleepers (known as ties in the US) are wooden. Wooden sleepers are normally treated with preservative to improve its life. They are easy to cut and drill and used to be cheap and plentiful. Concrete sleepers are much heavier than wooden ones, so they resist movement better. They offer less flexibility and can crack more easily under heavy loads. They also have the disadvantage that they cannot be cut to size for turnouts. Steel sleepers are used on more lightly used railways.

Ballast. Ballast is used to transfer (distribute) the load from the sleepers and to support the considerable loading of passing trains.The ballast also serves as a means of drainage (keeping water away from the rails and sleepers). Ballast material has to be strong, rough in shape, hard-wearing, resistant to deformation, stable and cheap. The best material for ballast is crushed rock with particles between 25 mm and 60 mm and between 25 and 50 in diameter. Other materials such as gravel, asbestos, shells, sand are also used. Ballast is packed between, below, and around the sleepers. Ballast is laid to a depth of 25 to 35 cm below wooden sleepers and of 30 to 40 cm below concrete ones. Periodically, ballast must be cleaned or removed and replaced with clean ballast to provide good drainage.

Cant. On curves the outer rail may be at a higher level than the inner rail. This is called superelevation or cant. This reduces the forces tending to displace the track and makes for a more comfortable ride for passengers.

Turnouts. Turnouts, also known as points (UK) and switches (USA), are the means of directing a train onto a diverging section of track.

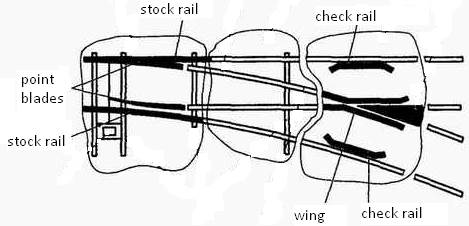

Turnouts

The most common type is a simple turnout. The moving part of the turnout is the point blade, one for each route. The blades of a turnout are moved remotely using an electrically operated point machine located to one side of the track. The two blades are fixed to each other by a tie bar to ensure that when one is against its stock rail, the other is fully clear and will provide room for the wheel flange to pass through cleanly. Either side of the crossing area, wing and check rails are provided to assist the guidance of the wheelsets through the crossing. A crossing is also referred to as a " frog".

A simple turnout